Stainless Steel Wet Blasting Machine, Wet Sand Blast Cabinet

Stainless Steel Wet Blasting Machine, Wet Sand Blast Cabinet Wet blasting, also known as vapor blasting or liquid honing

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | KF-1212w |

| Automation | Manual |

| Kind | Wet Sandblaster |

| Condition | New |

| Certification | CE |

| Customized | Non-Customized |

| Scope of Application | Aluminum, Stainless Steel, Al |

| Transport Package | Carton/Wooden |

| Specification | CE /IOS |

| Trademark | Kafan |

| Origin | China |

| HS Code | 8424899990 |

| Production Capacity | 200set/Month |

Product Description

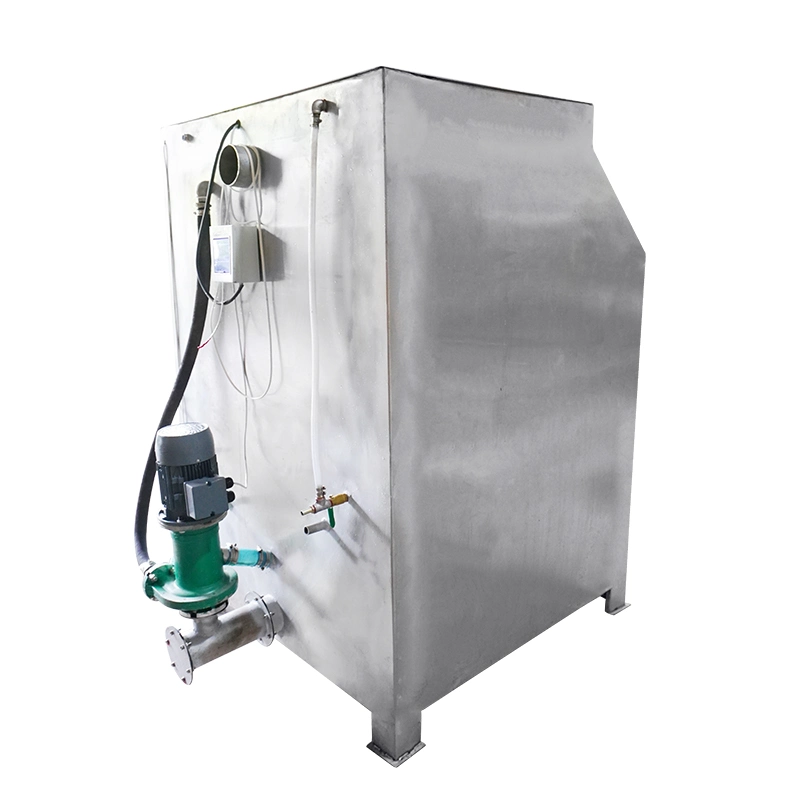

Stainless Steel Wet Blasting Machine, Wet Sand Blast Cabinet

Wet blasting, also known as vapor blasting or liquid honing, is the initial choice for applications requiring the highest quality of surface finish. Our wet blast cabinet is popular sold at worldwide market.

Our wet blasting cabinet are made of 3mm 304 stainless steel, which is durable, anti-rust and long lifespan.

Wet Blasting Cabinet Advantages

1. Clean Process. As the flushing action of the water, three is no media impregnation into the parts, and features dustfree when removing impurities.

2. Finer Finish: Water borne abrasive cushions the cleaning process, giving a finer and higher quality finish, especially for delicate or precise products.

3. Reduce Wear. The broken rate of media is decreased due to the cushioning from the water, and the blasting tool also gets less wear, as a results that wet blasting reduces production cost.

Kafan Wet Blasting Cabinet Features

Made 3mm thick stainless steel, rigid and anti-rust.

Low voltage windscreen wiper and wash facility to maintain visibility throughout

Durable wet blast gun with 8mm boron carbide nozzles specially for wet blasting process,

Reliable foot pedal controls the working of blast gun to increase operation safety.

A demister at the back of the machine for better view of blasting process.

Abrasive can be effectively recycled that causes less consumption.

Simple structured wet blast cabinet requires less maintenance.

Kafan Wet Blasting Cabinet Specifications

| Model | KF-1212W |

| Outer size | 1300*1600*2000mm |

| Working area | 1200*1200*800mm |

| Motor | 2.2Kw |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 2*18w saving lamps |

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads(for aluminum, stainless steel) Brown Aluminum Oxide(stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 380V/220V 3 phase (customized) |

Related Products

-

![Brown Fused Alumina Aluminium Oxide Corundum Powder Abrasives for Sandblasting and Abrasive Tools Bfa]()

Brown Fused Alumina Aluminium Oxide Corundum Powder Abrasives for Sandblasting and Abrasive Tools Bfa

-

![Aluminum Injection Machine Foundry Gravity Die Casting Machine]()

Aluminum Injection Machine Foundry Gravity Die Casting Machine

-

![0.5m/Min Auto Blasting Machine Sheet Metal Parts Frying Pots Soup Pots Cleaning]()

0.5m/Min Auto Blasting Machine Sheet Metal Parts Frying Pots Soup Pots Cleaning

-

![Movable Pressurized Sand Blasting Machine/Shot Blaster, Shot Blasting Cleaner/Sandblasting Equipment/Peening Tank/Derusting Tool]()

Movable Pressurized Sand Blasting Machine/Shot Blaster, Shot Blasting Cleaner/Sandblasting Equipment/Peening Tank/Derusting Tool