High Quality Spare Parts Roller Conveyor Shot Blasting Machine Price

Overview Product Description Roller conveyor machine is mainly used for processing long and (or) flat shape of the workp

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | Q6910, Q6915, Q6917, Q6920, Q6925, Q6930, Q6935 |

| Certification | CE |

| Feature | Critical Cleaning / Residue Free |

| Condition | New |

| Customized | Customized |

| Blasting Media | Steel Shot |

| Separation Mold | Full Curtain Wind Selection Type |

| Transport Package | Conventional Container Packing |

| Trademark | ANTAI |

| Origin | China |

| HS Code | 8424300000 |

| Production Capacity | 100 S/Year |

Product Description

Product Description

Roller conveyor machine is mainly used for processing long and (or) flat shape of the workpiece. These workpieces are continuously passed through the entering chamber, the shot blasting chamber and the cleaning chamber on a special conveyor roller table.

Qingdao ANTAI roller conveyor blast machines are designed as an optimal processing solution for steel plate/sheet metal, steel profile/beam/sections(H-beam, I beam, C-beam), steel pipes/tubes and steel structural framing, deformed steel bar etc, with residue from the shot's abrasive action handled via a blowing and brushing system that ensures every last trace is removed.With advice from our designers, you can decide to add a roller conveyor shot blasting system to your automatic treatment lines, including preheating, painting/coating and feed and transfer equipment.In addition to the standard version of the roller conveyor blast machine, Qingdao ANTAI has produced the non-standard model, designed specifically for the customers' workpiece details.

Application

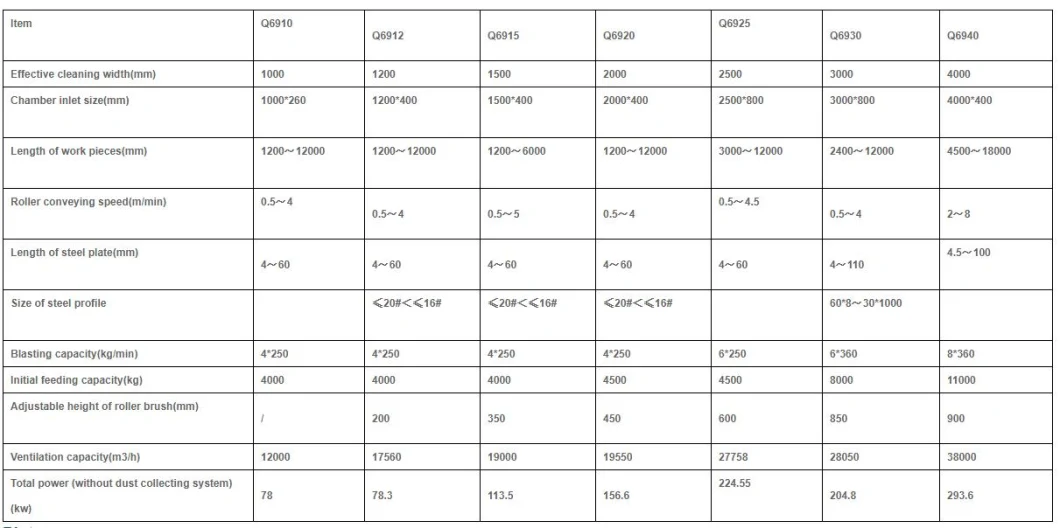

Process a wide variety of steel products such as plate, universal columns, beams, angles, flat, channel, bar, pipe, square and rectangle hollow sections.Product Parameters

Our Advantages

The Layout of blasting chamber and blast wheel is simulated by Solid Works software, specially designed by our senior designers.

Pneumatic control system is adopted to effectively prevent abrasive from being thrown and wounded.

Large blasting capacity and high blasting speed turbine can significantly improve cleaning efficiency and obtain satisfactory cleaning quality.

10mm rolled Mn13 steel plate in the blasting area with 12000 hours service life, resistant to impact and easy to replace.

High operational safety, Sufficient safety interlocking mechanism to ensure safety of operators.

Detailed Photos

Certifications

Main products

Company Profile

Qingdao Antai Heavy Industry Machinery has founded in 2003, formally changed to its current name in 2011. Located in the beautiful west coast of Qingdao, it is only 30 km to Qingdao seaport, convenient for export transportation. Our workshop area covers more than 15000 square meters, it is a research, design, manufacture, installation and consulting factory company for the surface finishing, environmental protection and foundry solution.Company has extensive experience and brings the technical and professional workers together, mainly produces shot blasting machine, sand reclamation equipment, molding equipment, and dust collector. Qingdao Antai is strong at providing non-standard design and manufacture according to customer specific needs.The company has passed ISO9 0 0 1: 2 0 0 8, ISO 1 4 0 0 1: 2 0 04, CE certificatio. Our company management strictly according to international standards ISO9 0 0 0 quality system implementation operation.We have established long term partnership with international brand suppliers, With quality products, competitive price andattentive service, our products are widely sold in domestic market and exported to Germany, Russia, Australia, India, Thailand, Sri Lanka and Indonesia etc more than 60 countries.We always adhere to "honesty is the best selling, personalized service is the final product. Customer satisfaction is the greatest impetus to the development of enterprises." Aim to establish a perfect quality management system and network information feedback system for filing separately for each customer, to provide customers with maximum caring and thoughtful, efficient and flexible full service.

we look forward to working with you and your company's sincere cooperation!

FAQ

1. How many days do you need to produce this machine?This is specially designed machine according to your specific requirement. From engineers designing to production completion, it needs about 45-55 days.

2. What does your factory do regarding quality control?We pay much attention to quality control from the very beginning to the end. Each machine is assembled and carefully tested before shipment.3. What's your machine quality guarantee?Quality guarantee time is one year. We choose world famous brand components to keep our machine in perfect working condition.4. Could you give installation and commissioning overseas? How long will it take?Yes, we supply overseas service, but customers need to pay for the engineers flight tickets and hotel, food. Small machines usually takes 5 days, while big machines usually takes about 20 days.5. How can I trust you to deliver the right machine as I ordered?We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is innovation, quality, integrity and efficiency. Antai id ALIBABA's golden supplier with BV and Tuv assessment. You can check with ALIBABA. We have never got complaint from our customers.Notice:

If the machine is not suitable for your workpiece, please tell us the following infromation:

What kind of workpiece will you clean?

What is the maximum size of the workpiece? (length, width and height)

What is the maximum weight of the workpiece?

What is the cleaning efficiency required?

According to your infomation, the most suitable machines will be designed for your workpieces

Related Products

-

![China Factory 7075 Aluminum Sand Blasting Hard Anodized CNC Machining Accessory Spare Parts]()

China Factory 7075 Aluminum Sand Blasting Hard Anodized CNC Machining Accessory Spare Parts

-

![Taa Brand Mg270 Tumble Belt Shot Blasting Machine Mini Blasting Machine]()

Taa Brand Mg270 Tumble Belt Shot Blasting Machine Mini Blasting Machine

-

![Harbor Freight Sandblast Cabinet, Sand Blasting Cabinet, Sandblasting Cabinets, Large Sandblasting Cabinet, Sand Blast Booth]()

Harbor Freight Sandblast Cabinet, Sand Blasting Cabinet, Sandblasting Cabinets, Large Sandblasting Cabinet, Sand Blast Booth

-

![Automatic Sand Blasting Booth / Dust Recycling Removal Sandblasting Room]()

Automatic Sand Blasting Booth / Dust Recycling Removal Sandblasting Room