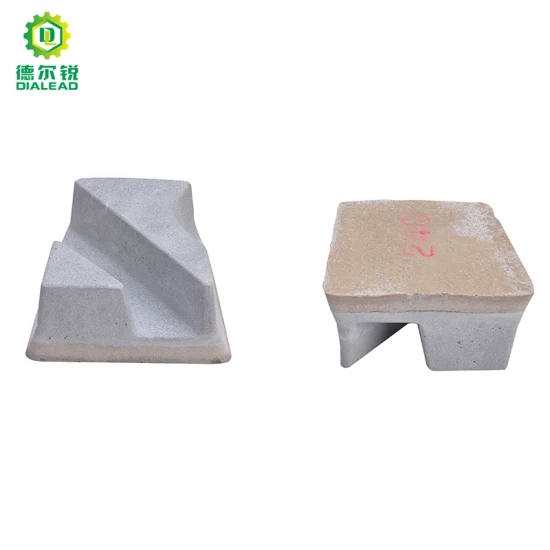

Customized Steel Aluminum Sand Blasting Casting Parts for Forklift Spare Parts Manufacturer Forklifts Parts

Overview Product Parameters Detailed PhotosFAQ 1.What about your quality?All of our products have good quality. Each cas

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | Customized |

| Coating | as Required |

| Machining Tolerance | +/-0.01mm |

| Standard | GB |

| Certification | CE, RoHS, ISO 9001:2008, ISO 9001:2015 |

| Molding | According Drawings |

| OEM/ODM | Available |

| Sample | Aviliable |

| Lead Time | 15-25days |

| Process | Sand/Die/Investment Casting |

| Machining Equipment | CNC Machining |

| Applications | Auto/Motorcycle/Agricultural/Ship/Railway/Hardware |

| Material | Iron/Steel/Alloy Steel/Stainless Steel/Aluminum |

| Transport Package | in Pallet or as Your Requrement |

| Specification | Customized |

| Trademark | Syncretic |

| Origin | Anhui China |

| HS Code | 7325101000 |

| Production Capacity | 2000 Tons Per Month |

Product Description

Product Parameters| Name | Casting Parts |

| Material | Iron/stee/aluminum/alloy steel/stainless steel |

| Process | Sand Casting, Shell Casting, Deburring, Sandblasting, Machining, Heat Treatment, Leakage test, Surface treatment, etc. |

| Machining equipment | CNC, Lathe machine, Milling machine, Drilling machine, Grinding machine |

| Lead time | 15-25 days, depending on the structure and size |

| Available software | Auto CAD, Solid work |

| Material standard | ISO, GB, ASTM, SAE, ISO, EN, DIN, JIS, BS |

| Surface treatment | Powder coating, Chrome plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, etc. |

| Machining equipment | CNC, Lathe machine, Milling machine, Drilling machine, Grinding machine |

| Quality control | The defective products rate is less 0.1%. |

| Application | Engine parts,Auto parts, Machinery Parts,Rail Train parts, Truck Parts,Tractor Parts,Construction Equipment ,Agriculture Equipment, Other industrial fields. |

1.What about your quality?All of our products have good quality. Each casting is processed through our QC staff with inspection records for every shipment. To guarantee the correct material specification and right mechanical properties, we have chemical analysis equipment, hardness tester, and tensile strength machine.2. What is your payment term?Usually we use TT payment, and the prepayment proportion is determined according to the order quantity, but mold and sample cost need to be paid in advance. 3. What's your delivery time ?The sample delivery time is generally about 10 days, and the order delivery period is determined by the order volume4. What is your quotation element?Design drawing (including material, weight, process, etc.) or sample, order quantity 5. Do you accept the 3D drawings?We accept 3D drawings. Software for specification drawings: Auto CAD, Solid work

Related Products